Volume 12 - Year 2025 - Pages 53-60

DOI: 10.11159/jbeb.2025.007

From Bench to Field: Predicting Biodegradable Mulch Film Lifetime from Laboratory Metrics

Crystal Cheng1,Bryan Huang2, Chenhao Zhang2, William Wen Zong3, Aaron Huang4, Linda Shi3

1Torrey Pines High School, San Diego CA

3710 Del Mar Heights Rd, San Diego, USA

crystal.tphs@gmail.com

2Canyon Crest Academy, San Diego CA

5951 Village Center Loop Rd, San Diego, USA

bryanhuangsd@gmail.com; chenhaozhang01@gmail.com

3University of California, San Diego

9500 Gilman Drive, La Jolla, CA, USA

wizong@ucsd.edu; zshi@ucsd.edu

4University of California, Santa Barbara

University of California, Santa Barbara, CA, USA

aaronahuang@ucsb.edu

Abstract - Growing environmental concerns have accelerated the development of biodegradable plastics, which are applied widely in organic waste collection bags, disposable food containers, and agriculture mulch films. Mulch films are widely used in agriculture to suppress weeds, retain soil moisture, regulate temperature, protect soil structure, and control pests, thereby enhancing crop yields. However, conventional polyethylene (PE) mulch films accumulate as plastic fragments, causing significant soil pollution. In contrast, biodegradable mulch films are completely assimilated by soil microorganisms as a carbon source, safely reintegrating into the ecosystem. The major critique for existing biodegradable films is that they perform well for short-growth-cycle crops (<90 days; e.g., potatoes, strawberries) but disintegrate prematurely in long-growth-cycle crops like cotton (requiring 120–150 days of coverage), leading to substantial yield losses. This study aims to enhance biodegradable film properties with advanced technologies, such as grafting biopolymers with inorganic fillers to improve tensile strength, UV resistance, and water barrier properties while maintaining biodegradability to align with cotton growth timelines to ensure functionality during cultivation and complete disintegration before the next planting season. The results obtained from laboratory aging tests (100 hours) and biodegradation tests (180 days) confirmed the biodegradable mulch film’s durability and decomposition profile. Subsequently, the field tests in cotton fields demonstrated that the optimized film with advanced technology sustained the support for cotton growth during 120–150 days, degraded on schedule, and delivered yields comparable to PE films.

Keywords: Biodegradable mulch film, disintegration, grafting, tensile strength, aging test, biodegradation test, field test

© Copyright 2025 Authors This is an Open Access article published under the Creative Commons Attribution License terms. Unrestricted use, distribution, and reproduction in any medium are permitted, provided the original work is properly cited.

Date Received: 2025-05-27

Date Revised: 2025-09-18

Date Accepted: 2025-10-01

Date Published: 2025-10-30

1. Introduction

Polyethylene (PE) mulch film is widely accepted agriculturally due to its myriads of agronomic benefits. Current PE mulch research demonstrates that mulch film can increase soil temperatures to accelerate plant growth and protection from various types of erosion damage, as well as reducing weed levels by up to 98%, ultimately supporting crop growth [1]. All of these characteristics are especially beneficial in arid and temperate climates, where it is necessary to optimize soil and water conditions. PE mulch film enhances crop growth through maximization of the root zone microclimate, which enhances productivity and farmers' yields [1]. PE mulch film is also appealing because of its low manufacturing costs, resilience in fields, and ease of application, and so it is widely used on both small-scale and industrial farms. However, the application of PE mulch film bears environmental consequences. PE mulch is made from petrochemical-derived plastics that cannot biodegrade, and postharvest film recovery is labor intensive and imperfect. Large quantities of mulch films are left in fields, where they fragment into microplastics over time. Trapped in the soil, they degrade soil structure and reduce water infiltration, among other negative consequences. Additionally, recycling the mulch is ineffective as it is already contaminated, and inappropriate disposal methods greatly damage the environment through pollution and toxic emissions.

To reduce the long-term environmental footprint of plastic mulching, biodegradable mulch films (BDMs) are a strong candidate for a more sustainable alternative. These BDMs mainly use polylactic acid or starch-based polymers that degrade through microbial activity under field conditions. BDMs are able to replicate the major functions and benefits of PE films such as preserving moisture, controlling temperature, and suppressing weeds at an even higher effectiveness than PE film—all without the need for removal and cleaning up after harvest [2, 3]. One example from China utilizing on-field studies found that under the same conditions, BDMs can match PE mulch in terms of yield and water use efficiency in a multitude of plants [2]. On top of environmental benefits, biodegradable films may also be reinstalled in fields after harvests without extra labor costs to remove old ones, thus assisting farmers in their work. Research has shown that especially in arid and semi-arid regions, the use of BDMs can increase crop yields by 28%, demonstrating levels of applications for BDMs [3]. Viability is further supported by tests conducted in Spain, in which target levels of degradation and yields over multiple years were achieved and followed European regulations, namely Regulation CEE 2092/91 [1].

While BDMs are effective, they face a critical problem: most commercial biodegradable mulch films disintegrate prematurely in long-growth cycle crops like cotton (requiring 120-150 days of coverage). However, this issue can be minimized through further materials development. Time-to-event decomposition models and field experimentation demonstrate the possibility of customizing the BDM degradation timeline to align with crop cycles. Thus, with careful tuning, these biodegradable mulch films can remain unimpaired during the plant growth stage, then start the process of degradation during or post-harvest–an extremely functional and sustainable advantage that can be customized to different agricultural environments [4]. Understanding this customization process is rooted in understanding the scientific mechanisms behind biodegradation and the ability to control it via material formulation. Researchers engineered a BDM via reactive grafting of poly(butylene adipate terephthalate) (PBAT/Ecoflex®) with talc filler to enhance tensile strength, to improve UV resistance, and to maintain hydrophobicity within cotton’s 120–150-day growth window while ensuring full biodegradability after harvest. The grafting modification between PBAT-talcum and Silane formed the copolymer that provides better strength (increased approximately 200%) and more effective water barrier (more than 70% moisture penetration reduction) compared to regular biodegradable mulch film. We will demonstrate the results of field validation after laboratory biodegradable confirmation.

2. Materials Preparation

In previous literature, grafting reactive extrusion has already been applied and used with polymers to generate copolymers [5]. Moreover, the usage of silane to graft polymers via reactive extrusion processes has also been previously accomplished [6]. To enhance the compatibility and mechanical properties of PBAT blended with talc filler, our study employs a film manufactured using a reactive extrusion process. Silane-functionalized PBAT is grafted to talc, which is hydroxyl-rich, using a free-radical initiator (Luperox 101). This forms covalent Si-O-Si bonds that bridge the organic polymer and inorganic filler. This method aims to overcome interfacial weakness in PBAT/talc composites while reducing material costs. Afterwards, Soxhlet extraction, Fourier-transform infrared spectroscopy (FTIR) tests of the PBAT/talc/silane blend, as well as mechanical tests have also confirmed the structural change of PBAT, as well as the increased tensile properties in machine and transverse direction. Ultimately, the study confirmed the PBAT mulch film under such grafting refinement has a significant improvement on mechanical properties, making it comparable to traditional PE mulch film in terms of utility.

2.1. Material Synthesis and Grafting Confirmation

PBAT (Ecoflex® FBX 7011, BASF) was reactively grafted with talc (Luzenac 20M00S, ~6 µm, dried) using vinyl-trimethoxysilane (VTMOS) or vinyl-methyldimethoxysilane (VMDMOS) (Gelest) as coupling agents and 2,5-Bis(tert-butylperoxy)-2,5 dimethylhexane (Luperox 101, Sigma-Aldrich) as a free-radical initiator. PBAT (700g) was hand-mixed sequentially with the initiator (0.1 wt% of PBAT), silane (0.5 or 1.0 wt% VTMOS or VMDMOS of PBAT), and talc (300g). The mixture was extruded in a co-rotating twin-screw extruder (Century ZSK-30, L/D=40:1) at 150 rpm. The temperature profile ranged from 90°C (feed) to 175°C (die). Strands were cooled and pelletized.

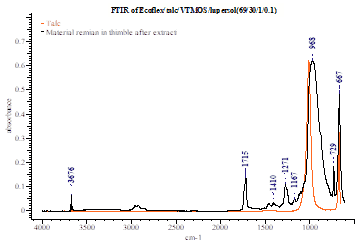

Grafting was confirmed via solvent extraction (dichloromethane, 24hr) and FTIR. Unmodified PBAT/talc (69/30) blends showed complete separation: extracted pure PBAT and residual pure talc (FTIR peaks: 1009 cm⁻¹ Si-O-Si, 670 cm⁻¹ Si-O-Mg). In contrast, silane-modified blends (e.g., PBAT/talc/VTMOS/Luperox 70/30/1/0.1) yielded only ~55 wt% extractable PBAT. FTIR of the non-extractable residue showed characteristic peaks of both PBAT (1715 cm⁻¹ C=O, 729 cm⁻¹ benzene, ~2950 cm⁻¹ -CH₂-) and talc (shifted Si-O-Si peak at ~968 cm⁻¹, 667 cm⁻¹ Si-O-Mg), as shown in Figure 1, confirming PBAT-talc copolymer formation via Si-O-Si bonds from hydrolyzed silane.

2.2. Film Processing and Mechanical/Barrier Properties

Modified composites and unmodified control were blown into films (~10 µm) using a single-screw blown film line (Killion, screw Ø25.4 mm, L/D=25:1, die gap 1.5 mm, melt temp ~150°C, screw speed 15 rpm). Tensile properties (ASTM D882) were measured. Results are summarized in Table 1 and Table 2.

Table 1. Tensile Properties (Machine Direction) of blown films

|

Sample |

% Free Radical Initiator |

Type and (% Amount of Silane) |

Young’s modulus (MPa) |

Yield Stress (MPa) |

Tensile Stress (MPa) |

Break Elongation (%) |

|

1 |

0 |

0 |

117.21 |

12.69 |

14.20 |

600 |

|

2 |

0.1 |

VTMOS (0.5) |

391.97 |

39.99 |

39.99 |

300 |

|

3 |

0.1 |

VTMOS (1.0) |

378.18 |

31.72 |

32.41 |

230 |

|

4 |

0.1 |

VMDMOS (1.0) |

330.95 |

29.30 |

29.65 |

470 |

Table 2. Tensile Properties (Transverse Direction) of blown films

|

Sample |

% Free Radical Initiator |

Type and (% Amount of Silane) |

Young’s modulus (MPa) |

Yield Stress (MPa) |

Tensile Stress (MPa) |

Break Elongation (%) |

|

1 |

0 |

0 |

118.59 |

9.65 |

10.34 |

300 |

|

2 |

0.1 |

VTMOS (0.5) |

349.56 |

22.75 |

22.75 |

270 |

|

3 |

0.1 |

VTMOS (1.0) |

395.07 |

25.51 |

26.20 |

200 |

|

4 |

0.1 |

VMDMOS (1.0) |

355.77 |

24.13 |

24.13 |

430 |

Based on materials properties and cost considerations, we choose sample #2 as a modified formula for all the further tests. Water vapor transmission rate (WVTR) test was conducted at 10 micron film under the condition at 38oC, 90% PH for 24 hours. The test results demonstrate that water retention was improved significantly in sample #2. The WVTR was decreased from 1132 g/(m2·24hr) (sample #1) to 382.7 g/(m2·24hr) (sample #2), which meets the mulch film standard requirement <800 g/(m2·24hr).

3. Aging Test

An aging test of biodegradable film samples (with/out grafting) was evaluated in accordance with the national standards to assess the mulch film’s durability and resilience over a longer period of time through shorter periods of extreme weathering. The test conditions included an irradiance of 173.4 W/m² at 340 nm, a black panel temperature of 65 ± 3 °C, a relative humidity of 50 ± 10% RH, and a cyclic light/spray exposure for 100 hours. After aging, tensile tests were performed on aged films, only elongation results were recorded in Table 3 per standard requirements. The aging test results show significantly improved resistance to environmental aging after grafting reaction. Sample #2 comfortably meets and exceeds the national standards for post-aging mechanical performance.

Table 3. Results of aging test

|

Orientation |

Unit |

Requirement |

Post Aging Elongation |

|

|

Sample #1 |

Sample #2 |

|||

|

Machine Direction |

% |

≥80 |

11 |

160 |

|

Transverse Direction |

% |

≥100 |

29 |

230 |

4. Biodegradation Test

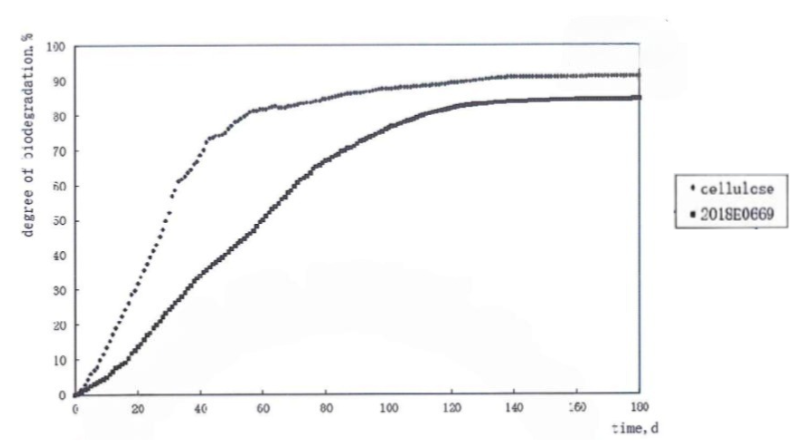

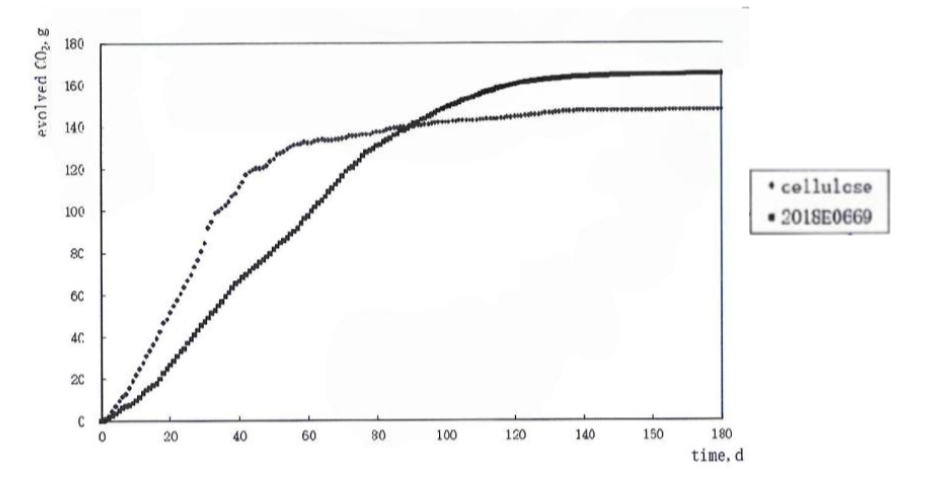

Biodegradability under composting conditions was assessed according to ISO 14855 or equivalent standards. Test material (Sample #2 film) and positive control (semi crystalline cellulose) were mixed with mature compost in vessels maintained at 58±2°C and above 50% moisture levels. The total organic carbon (TOC) was around 12%, the pH was about 7.8, and the volatile solids content (VS) above 55%. Evolved CO₂ was monitored continuously by infrared analysis over 180 days. The degree of biodegradation was calculated as (CO₂ from test material) / (Theoretical evolved carbon dioxide (ThCO2)) x 100%, and disintegration was assessed visually and gravimetrically (mass loss). The degradation data was collected over time. As shown in Figure 2 and Figure 3, in standard compost pile, the observed degradation rate is at approximately 24% per month in the first three months, slow down to 18% in Month 4, and then reached a plateau of around 90% mineralization by day 120, achieving an average of 92.8% biodegradation by day 180. Plant growth (ryegrass, cress) and earthworm survival tests in compost-amended soil showed no adverse effects compared to blank compost controls, meeting ecotoxicity requirements. As shown in Table 4, gravimetric analysis showed a 98.4% average disintegration in sample 2. Visual observation confirmed the progressive fragmentation and disappearance of our test material. Furthermore, all of the results of sample #2 met the ASTM D6400 requirements.

Table 4. Degree of Disintegration

|

Apparatus Number |

Total dry solid in test sample input (g) |

Total dry solids in the residual test sample (g) |

Degree of disintegration (%) |

|

#1 |

1019.0 |

17.1 |

98.3 |

|

#2 |

1019.0 |

15.9 |

98.4 |

|

Average |

98.4 |

5. Field study for Cotton Production

A field study was conducted in China to evaluate the effectiveness of using grafted biodegradable mulch film (sample #2) to aid cotton planting, including its degradation process in the field. Mulch films were placed over TAHE 2 cultivar cotton, an early-to-mid-maturing upland cotton type that requires 120 days to mature. The mulch films were placed on machines and installed with standard practices.

5.1. Methods and Measurements

Three treatment groups were tested: 10.2 μm thick biodegradable film (sample #2), 12.1 μm thick PE film, and bare soil (control). A thinner BDM was chosen due to stronger tensile properties of the biodegradable films vs. PE mulch films, but both types of films were laid down with a cross-sectional width of 205 cm. A randomized block design was conducted with three replicates per treatment group. Traditional bare soil served as control.

Throughout the planting time, ground temperature was measured by using automatic temperature recording probes (accuracy ±0.2 °C) which were buried at a depth of 10 cm. Data was recorded every 60 minutes at each of the three different locations per treatment group, then daily average temperatures were calculated. The state of degradation of the films was observed every 10 days post-application and classified by stage. The stages were determined by the size of cracks on the film: induction (≤2 cm cracks), cracking (2–20 cm), fragmentation (>20 cm), disintegration (residues ≤16 cm²), and disappearance. Plant height, boll count, average single boll weight, and yield were measured as crop metrics during the harvest.

5.2. Results

Although biodegradable mulch films were slightly less effective than traditional PE films at increasing plant height and cotton boll weight, the number of cotton bolls produced per plant and the overall yield per hectare were higher for biodegradable films. Overall levels of productivity for the two products were very similar.

Table 5. Effect of different mulch film covering on cotton yield

|

Plant Height (cm) |

Cotton bolls per plant |

Avg boll weight (g) |

Cotton yield (kg/hectare) |

|

|

PE Film |

80.3 ± 0.5 |

6.42 ± 0.20 |

4.84 ± 0.10 |

5494.5 ± 62.5 |

|

BDM Film |

79.8 ± 0.6 |

6.48 ± 0.13 |

4.82 ± 0.11 |

5518.6 ± 53.2 |

|

No Mulch Film |

76.4 ± 0.6 |

3.20 ± 0.10 |

4.20 ± 0.10 |

2379.2 ± 84.3 |

Table 5 displays the statistical results of the cotton yields, comparing plant heights, the number of cotton bolls per plant, and weights of each boll for cotton grown with different films. Whereas cotton plants covered in mulch films both exhibit increases in height vs. uncovered plants, there is not a statistically significant difference in plant height using PE vs. BDM film. It may be observed that the presence of mulch films significantly affects the yield of cotton. The yield of biodegradable mulch film is the highest, though there is no significant difference in the yields of different mulch films. The yields of cotton cultivated on land with different mulch films are 2.3 times that of cotton cultivated on bare land. This is mainly reflected in the number of cotton bolls per covered plant (3.22–3.28 more than plants cultivated on bare land) and the 0.42–0.44 g increase in individual boll weight.

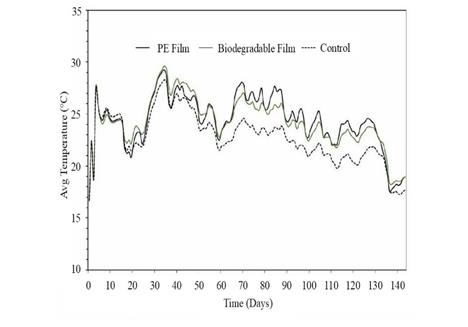

The results of the study demonstrated that when it came to soil temperature measurements, the biodegradable mulch film outperformed PE film, increasing soil temperature of 10 cm by 0.35–0.89°C during early growth (0–60 days) (Figure 4). There was no significant difference in terms of moisture retention and weed control.

The disintegration speed of films were then matched with crop cycles (Figure 5). The degradation timelines were followed as planned for cotton growth needs. Cotton was sown on May 5. 120 days later, the mulch film surface had multiple (2-3 per square meter) natural cracks or holes with cross-sections below 2 cm, entering the induction period. 141 days after the cotton was sown, natural cracks with cross-sections between 2 cm and 20 cm began to appear, entering the cracking period. 152 days after the seeds were sown, it entered the fragmentation period, in which the film surface began to have natural cracks more than 20 cm long. 154 days after planting, it entered the disintegration period: the mulch film on the surface lost its flexibility and fragmented, with mulch film fragment averaging areas below 16 cm2. Finally, full degradation was achieved by harvest. It can be seen that after the biodegradable mulch film entered the induction period, the subsequent degradation time was relatively fast, and it only took one week to transition from the large cracking period to the fragmentation period. There was essentially no change in the visible structure of the PE film.

Conclusions

The study successfully developed and validated high-performance BDMs specifically engineered for long-growth-cycle crops like cotton. As demonstrated by field tests, reactive grafting of PBAT with talc filler using vinyl-silane coupling agents significantly enhanced key properties, such as mechanical strength, durability, moisture retention, and biodegradability. In particular, grafted PBAT achieved tensile properties comparable to PE film and demonstrated near-complete mineralization and disintegration under composting conditions within 180 days, with no ecotoxic effects. The optimized BDM provided equivalent agronomic support (soil warming, moisture retention, weed control) and crop yield to conventional PE film throughout the critical 120-150 day cotton growth period. Critically, it then degraded over a predictable timeline aligned with the crop cycle, entering disintegration shortly after boll opening and achieving full degradation post-harvest before the next planting season. This technology effectively resolves the major limitation of premature disintegration of existing BDMs for long-duration crops. Thus, farmers avoid yield losses associated with premature disintegration. By enabling customization of degradation kinetics through material formulation, it offers a viable, sustainable solution to replace persistent PE mulch, eliminating plastic pollution and retrieval costs without compromising agricultural productivity.

This framework provided a generalized solution for large-scale agricultural plastic waste management. The new technologies extended the shelf life of biodegradable mulch from 1.5 months to 4.5 months, which can cover almost all long-cycle crops including corn, rice and peanuts. After the plant cycle, the biodegradable mulch film will decompose completely to water, CO2 and humus. This new technology has significant potential to reduce agricultural plastic waste at scale by eliminating disposal issues and contributing organic matter to the soil. Further quantity study with standardized testing on the film biodegradation in the field will provide foundation for the evaluation of prognostics factors which determine the time to degradation and enable the characterization of the compost process. In addition, the analysis for the long-term effect on the soil will be performed to ensure the BDMs are sustainable and effectively integrated into agricultural practices. Whole life cycle analysis and continued innovation are needed to optimize BDM materials and manufacturing processes to enhance sustainability and affordability.

Acknowledgements

This study was supported by BEFTRE Green Technology LLC.

References

[1] S. Kasirajan and M. Ngouajio, "Polyethylene and biodegradable mulches for agricultural applications: a review," Agronomy for Sustainable Development, vol. 32, no. 2, pp. 501-529, Jan. 2012, doi: https://doi.org/10.1007/s13593-011-0068-3. Available: View Article

[2] B. Guo, Z. Yang, W. He, and J. Liu, "Application effectiveness and problems of biodegradable mulch," Chinese Journal of Agrometeorology, vol. 44, no. 11, p. 977, Nov. 2023.

[3] E. Liu, L. Zhang, W. Dong, and C. Yan, "Biodegradable plastic mulch films in agriculture: feasibility and challenges," Environmental Research Letters, vol. 16, no. 1, p. 011004, Jan. 2021, doi: https://doi.org/10.1088/1748-9326/abd211. View Article

[4] M. Yin, Y. Li, H. Fang, and P. Chen, "Biodegradable mulching film with an optimum degradation rate improves soil environment and enhances maize growth," Agricultural Water Management, vol. 216, pp. 127-137, May 2019, doi: https://doi.org/10.1016/j.agwat.2019.02.004. View Article

[5] G. Moad, "The synthesis of polyolefin graft copolymers by reactive extrusion," Progress in Polymer Science, vol. 24, no. 1, pp. 81-142, Apr. 1999. View Article

[6] K. Sirisinha and K. Kawko, "Crosslinkable polypropylene composites made by the introduction of silane moieties," Journal of Applied Polymer Science, vol. 97, no. 4, pp. 1476-1483, May 2005, doi: https://doi.org/10.1002/app.21872. View Article

[7] Jiaqian Cui, Junwei Tang, Xijiao Bian, Jungang Jiang, Yifan Zhang, and Lei Wang. "A Lignin-Based Biodegradable Mulch Film with Zn2+ Coordination Networks for Sustainable Agriculture," Biomacromolecules, Vol 26, issue 8, p.5195-5203. Jul. 2025. View Article

[8] Haihe Gao, Changrong Yan, Joann K. Whalen, Wenqing He, Hongjin Liu, Jixiao Cui, Daozhi Gong, Karen Mancl, Qin Liu, and Xurong Mei. "Biodegradable mulch films support root proliferation and yield in water-saving rice production," Biomacromolecules, Vol 26, issue 8, p.5195-5203. Jul. 2025. View Article

[9] Dada OI, Habarakada Liyanage TU, Chi T, Yu L, DeVetter LW, and Chen S. "Towards sustainable agroecosystems: A life cycle assessment review of soil-biodegradable and traditional plastic mulch films," Environmental Science and Ecotechnology, 2025,24. https://doi.org/10.1016/j.ese.2025. View Article